So this will be my first post. My name is David Wise and I am currently a sophomore in Mechanical and Ocean Engineering at Massachusetts Institute of Technology. I started this blog to document the various projects and other cool stuff I do while I am here at MIT. I have tried to update the pages on the sides with projects that I have already made substantial progress on. But now that is enough about me. Let's talk about something substantially more interesting...

This is the name of the Electric Go-Kart that

Jackie and I have been building as part of 2.007: Design and Manufacturing 1. We will eventually compete with a handful of other kids that have been building electric scooters, roller blades, skateboards, and tricycles under the tutelage of

Charles in a race in May. We are pretty far along with the project at the moment (just putting on some finishing touches) but I will try and go through the construction from the beginning

|

MelonKart after its first official Garage Run (1:35, 23.5 W-H)

|

|

| Some of the preliminary Solidworks Models of MelonKart |

|

| Measure Twice, Cut Once... |

Here is the start of our construction. We bought the red plastic seat form Summit G racing and about 35 ft of 1" x1" 16 Ga square steel tubing from Ebay. We cut the frame tubes to the correct length and then we cleaned the ends with a grinder and a wire wheel to prep them for welding. We were planning on using the TIG welder in the metal shop in N52 to do the welding. The only problem being that neither Jackie or I had ever used the TIG welder before...

Which is where Dario came in. He is on the Formula SAE team here and one of my suitemates in Burton-Conner. He offered to teach us how to use the TIG welder and helped us tack the frame together.

|

| Me welding a practice piece of tubing before working on the actual frame. |

Now that the frame had enough welds on it to be load-bearing, we began to attach our snazzy red seat.

|

| Drilling holes for the mounting brackets |

|

| The seat is mounted! |

I spent a good chunk of my time designing an fabricating the uprights and the steering linkage. This is the front left upright after I had welded it.

|

| Sizing the bolt that would act as a kingpin |

I did some FEA analysis on the axles that came with the wheels from Monster Scooter Parts that we were planning on using and decide that we were pushing the limits with a 10 mm diameter axle if it was cantilevered. I designed a set of aluminum step shafts that would work with 6903 bearing to replace the stock ones. I got to learn to use the CNC lathe at the Edgerton Student shop to manufacture them, which definitely saved some time!

Here we are sizing the length of the steering column. We decided to use an old endcap from an underwater vehicle that we found in the MRT lab as a steering wheel, for nostalgia.

Skipping ahead a little bit

We have finished the front steering linkage, mounted all the wheels and the questionable quality brake (we salvaged the brake cable and handle from a dumpster) and mounted the namesake of our project: MelonMotor.

|

| Rolling Chassis: COMPLETE! |

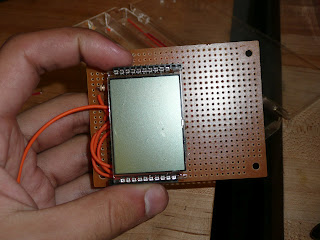

After an all-night marathon, the entire electronic system is in place. The orange batteries were donated by A123 and are Li-Ion Phosphate and we are currently using one of the KBS motor controllers from Kelley. The powertrain is a 4.5:1 ratio with #25 chain.

|

| Charles programming the controller. |

IT'S ALIVE!!!!!!!!!!

MelonKart works! We even got to debut it to an audience of about 200 middle schoolers. Ed Moriarty of the Edgerton Center was asked to give a keynote speech about engineering and asked me if I had been working on anything cool recently. I thought MelonKart fit the bill, so in the middle of his introduction I got to drive in to Johnson rink honking the horn and do a loop of the building before parking in the front while Ed finished his speech. It was a ton of fun!

|

| Adrian testing MelonKart later that day |

and to culminate this exceptionally long post: the video of the parking garage run #1

so this is the current state of our project. I will try my best to update as much as possible and Thank you for reading!